Project Overview Production execution for clean beauty brand Cocokind’s consumer product packaging, translating established brand design guidelines into production-ready carton dielines and label specifications across their skincare product line.

Client Cocokind – Clean, conscious skincare brand

Project Details

- Timeline: November 2019 – January 2020

- Role: Freelance Packaging Production Artist

- Scope: Label and carton production for multiple SKUs across product line

Product Line Developed

- Resurfacing Sleep Mask (1.7 fl oz / 50ml jar and secondary carton packaging)

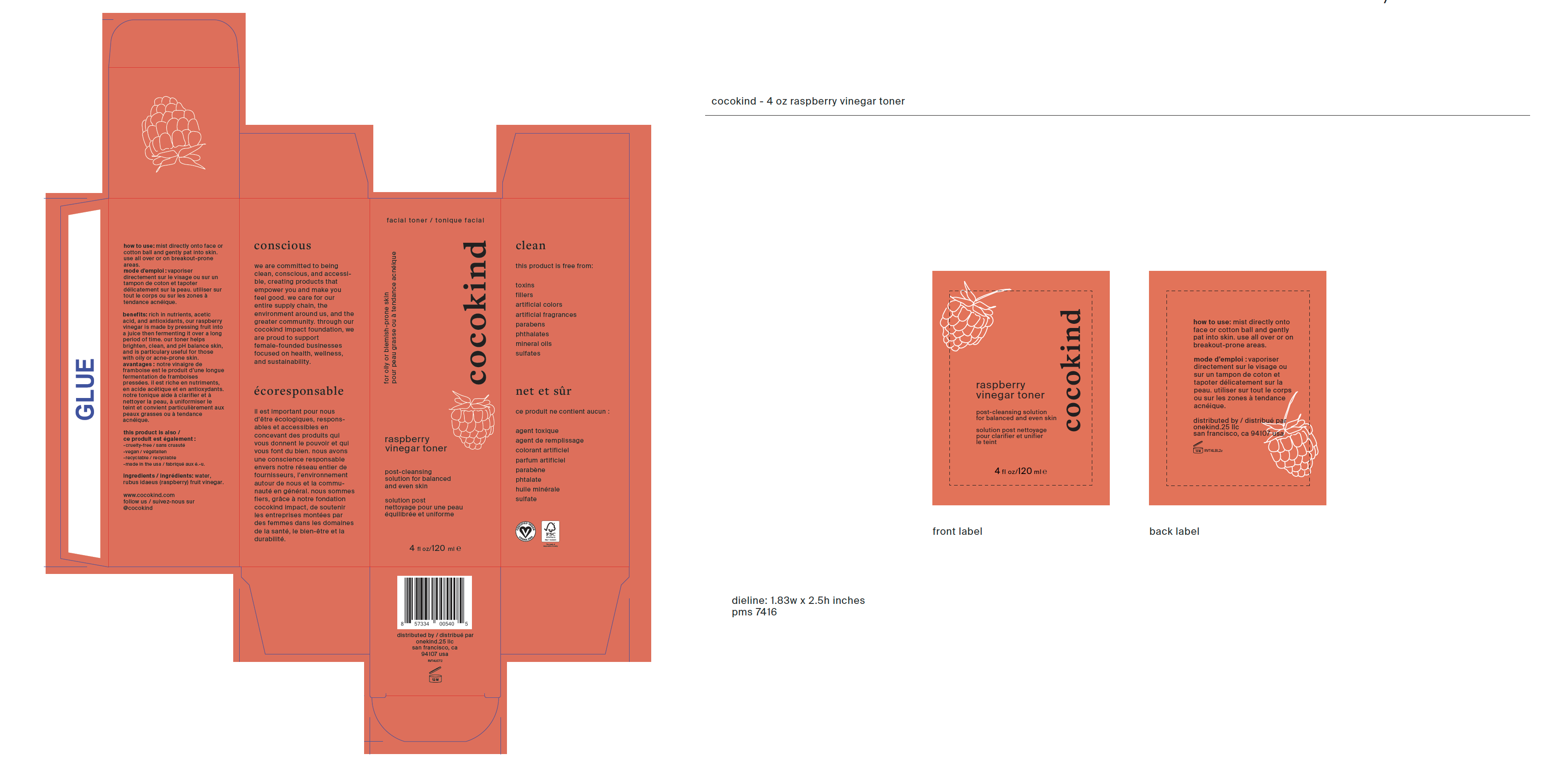

- Raspberry Vinegar Toner (4 fl oz / 120ml bottle with front and back labels, and secondary carton)

- Additional product packaging across skincare range

Project Scope & Responsibilities

Primary Deliverables:

- Production-ready carton dielines with proper fold lines, glue flaps, and structural specifications

- Front and back label artwork prepared for flexographic printing

- Technical file preparation ensuring brand consistency across product line

- Coordination with printing vendors for specification accuracy

Key Responsibilities

- Adapt existing brand design guidelines to various package formats

- Create precise structural dielines for carton manufacturing

- Prepare label separations and print specifications

- Ensure regulatory compliance (ingredient lists, usage instructions, safety warnings)

- Maintain typography, color, and iconography consistency per brand standards

- Generate production files ready for offset and flexographic printing

Technical Specifications

Carton Production – Raspberry Vinegar Toner Example:

- Dieline Dimensions: 1.83″ x 2.5″ (approximate flat dimensions)

- PMS Color: 7416 (Cocokind signature coral/red)

- Print Method: Offset printing on SBS (Solid Bleached Sulfate) paperboard

- Finish: Matte coating for natural brand aesthetic

- Structure: Tuck-end folding carton with glue flap

- Special Features: Window die-cut consideration for product visibility

Label Production – Raspberry Vinegar Toner Example:

- Front Label: Brand identity with product name and key messaging

- Back Label: Ingredient list, usage instructions, brand story, certifications

- Print Method: Flexographic printing

- Material: Pressure-sensitive paper or film label stock

- Finish: Gloss laminate to align with brand aesthetic

Resurfacing Sleep Mask Packaging:

- Primary Package: Glass jar with white lid (50 mL capacity)

- Secondary Package: Vibrant blue carton with white typography

- Label Application: Direct print or wrap-around label on jar

- Information Hierarchy: Product name, key benefits, usage, ingredient transparency

Brand Guidelines Implementation

Visual Identity Standards:

- Color Palette: Bold, saturated primary colors (cobalt blue, coral red, golden yellow, lime green)

- Typography: Clean sans-serif for brand name and product titles, readable serif/sans for body copy

- Iconography: Hand-drawn botanical illustrations (raspberry, leaves, lotus flowers)

- Brand Voice: Transparent, educational, eco-conscious messaging

- Certifications: Vegan, cruelty-free, Leaping Bunny certification display

Content Requirements:

- Bilingual packaging (English/French for Canadian compliance)

- Comprehensive ingredient lists following INCI nomenclature

- Usage instructions and product benefits

- Sustainability messaging (“écoresponsable”, recyclability information)

- Company contact information and website

- Barcode placement and specification

Production Challenges & Solutions

Challenge 1: Design Guideline Translation to Production Specifications Existing brand designs needed conversion to print-ready files with proper bleeds, die lines, fold lines, and technical specifications.

Solution:

- Created detailed dieline templates based on bottle and jar dimensions

- Built library of reusable carton structures for consistent production

- Established standard bleed and safety zones for all package formats

- Generated comprehensive specification sheets for print vendors

Challenge 2: Multi-Panel Information Hierarchy Cartons required extensive information (ingredients, instructions, certifications, bilingual text) organized across limited space while maintaining brand aesthetic.

Solution:

- Prioritized information based on regulatory requirements and brand importance

- Utilized interior and exterior carton panels strategically

- Maintained consistent typography system for readability at small sizes

- Balanced required text density with brand’s clean, minimal design approach

Challenge 3: Color Consistency Across Print Methods Products used different printing methods (offset for cartons, flexo/digital for labels) requiring color management across processes.

Solution:

- Specified PMS spot colors for brand consistency (PMS 7416 for coral)

- Provided color build formulas for process printing when necessary

- Created color matching standards for vendors

- Reviewed press proofs to ensure brand color accuracy

Challenge 4: Structural Accuracy for Manufacturing Carton dielines needed perfect precision to ensure proper folding, gluing, and product fit.

Solution:

- Worked from physical product samples to verify dimensions

- Created mockups to test structural integrity before production

- Coordinated with packaging manufacturers on material thickness and tolerances

- Provided detailed assembly notes for production teams

Challenge 5: Regulatory Compliance Clean beauty brand required transparent ingredient labeling and compliance with cosmetic regulations across markets.

Solution:

- Worked from physical product samples to verify dimensions

- Created mockups to test structural integrity before production

- Coordinated with packaging manufacturers on material thickness and tolerances

- Provided detailed assembly notes for production teams

Skills Demonstrated:

- Structural packaging design and dieline creation

- Brand guideline interpretation and application

- Multi-format packaging production (cartons, labels, jars)

- Print specification for offset and flexographic processes

- Cosmetic industry regulatory knowledge

- File preparation for multiple print vendors

- Typography and information hierarchy

- Color management across print processes

- Mockup creation and structural verification

- Vendor coordination and technical communication

Production File Deliverables

Complete Package for Each Sku:

- Carton dieline with fold lines, cut lines, glue flaps clearly marked

- Label artwork with trim marks and bleed specifications

- Color specifications (PMS callouts or process builds)

- Font specifications and usage guidelines

- Barcode files with proper quiet zones and specifications

- Print-ready PDFs with embedded fonts and proper color profiles

- Structural notes for manufacturing

- Material and finish recommendations

Supporting Documentation:

- Mockup renderings for client approval

- Proof approval records

- Vendor specification sheets

- Quality control checklists

Design Philosophy Alignment

Successfully maintained Cocokind’s brand values throughout production:

- Conscious: Sustainable material specifications, recyclability information

- Clean: Minimalist design aesthetic with transparent ingredient disclosure

- Accessible: Clear information hierarchy and multilingual support

- Authentic: Hand-drawn botanical illustrations and approachable messaging

- Eco-responsible: Material selection and sustainability callouts

Results & Impact

- Produced consistent, brand-compliant packaging across multiple product launches

- Enabled smooth manufacturing process through accurate technical specifications

- Maintained brand integrity across different package formats and printing methods

- Supported brand’s transparency and sustainability messaging through thoughtful information design

- Created scalable template system for future product development

Professional Value

This project demonstrates expertise in:

- Brand guideline adherence and consistency management

- Cosmetic and skincare packaging regulations

- Multi-SKU production coordination

- Structural packaging and dieline engineering

- Clean beauty industry knowledge

- Flexographic and offset print production

- File preparation for contract manufacturing

- Detail-oriented technical execution